Last update 03/03/2015

Surefoot

Mic Stand

bases and Accessories

The Surefoot information has moved to http://www.surefootstands.com

Custom Applications and

modifications:

Larry Gatlin's Guitar Stands

Ultra High Stability Orchestral Music Stand

Lighting fixture ground support

Boom Modification kits

Our mission is to manufacture a very high quality product entirely on-shore in the United States, with NO offshore content if at all possible.

We toured for a number of years, and our goal is to manufacture robust and versatile microphone support products that we would want to use ourselves, and in some cases, could never find.

We hate lame mic stands, and we are really

unhappy that manufacturing of almost all of them has been moved offshore,

with far less than adequate resulting quality.

There is a disposable cheap product market, but we are not interested in

that market.

Our products are field serviceable and we support them. If someone finds a

flaw in our products, we're going to fix it and make a retrofit available.

We have sought out onshore companies: Foundries, machine and CNC shops,

tubing suppliers, precision plastics machining houses (tube slides), and

paint suppliers/jobbers; who employ people stateside. We require assurance

that parts and services that we use originate onshore. We visit facilities to know

our suppliers and develop relationships.

This is a Pro Product, and we hope to see them in wide use in touring and

high-end installations.

We hope that when people buy tickets to productions, that some little part

of that ticket winds up going back into the American economy, and

specifically the manufacturing economy.

This "onshoring" has been challenging. Key manufacturing in the US has

been eroded to the point that it's tough to find these suppliers. Some

things we need are only made offshore, but we have no quarrel with quality

manufacture in Europe, and some component pieces are European through US

Distributors.

We can live with that.

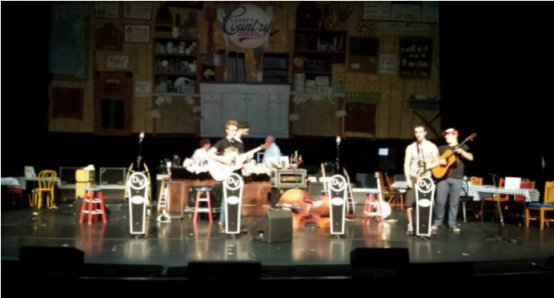

Starlite Theater - Branson, MO Mic stand upgrade

We're happy to have provided seven new Surefoot stands to Starlite Theater.

Compare the footprints of the Surefoot bases on Kick and Snare with the

conventional base on the overhead to their right.

Drum riser congestion solved.

When backline riser depth is at a premium,

Surefoot will free up more room.

Again, compare the footprints of Surefoot and

a conventional lightweight tripod stand.

Dailey and Vincent at Starlite - Soundcheck

So far every performer I have had come through this theater has commented on these bases.

I love them!"

Greg Rowan, House Sound Engineer, Starlite Theater

The Surefoot Line and Options

What started out as an effort to retrofit and improve existing mic stand

products has grown into a developing line of high-quality, rugged, Made In

USA bases; as well as retrofit kits for existing products and special or

custom applications.

A line of

stand poles, booms, and other accessories/Modifications/Enhancements to other products are in development, along with a

line of truck-pack dimensioned trunks and transport cases.

Our stand poles and boom tubes will be available in 6061-T6 aluminum, or

4130 Chromoly steel.

All threading is compatible

and compliant with industry standard microphone hardware and poles, 5/8",

7/8", and 1 1/8" tubing and standard threading pitches.

Other tappings are available on order. If we can get a tap for your

threading, we can do it.

Left to Right - Longfoot with lighting

fixture ground support adapter, Longfoot with Atlas MS20 pole, Surefoot with

Atlas MS12 pole, and Surefoot with K&M 199 pole.

Folded and ready to pack.

3rd St. R & D will, in the first quarter of 2014, release the first new folding cast iron mic stand base design in 25 years, which folds down into a very tidy and easy to pack form and is mic stand trunk friendly.

Rapid Setup and Tear Down On The Road

The leg flanges are heavily reinforced with

cast-in ribs.

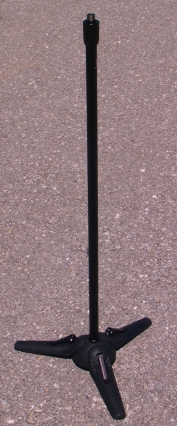

Surefoot with Atlas MS12 Pole

All of our Mic Base products and retrofit products, as well as our future proprietary boom products

feature locking levers for rapid setup and tear down. No longer is it

necessary to screw bases on and off of stand poles every night when loading

out. A few quick flips of the levers, and in seconds the base / pole

combinations are ready to drop vertically into a compartmented road trunk.

Tomorrow you pull them out of the trunk, flip a few levers, and they are ready to go.

BASES

There are two versions at present, the Surefoot has a footprint slightly larger than a quality round base, while the Longfoot has a larger footprint for greater stability while remaining much smaller than imported lightweight tube bases and stands.

Surefoot is

available tapped for either 5/8" or 7/8" poles.

The 5/8" tapping is specifically

intended for direct attachment to specialty mics like

Audix

Microboom

Choir/Orchestra mics.

Longfoot is available tapped for either 7/8" or 1-1/8" poles.

If you like your

existing 7/8" thread poles, they will screw right on to our bases.

Note: Some inexpensive Music Store stand

poles have welded washers instead of jamnuts and interfere with the rotate

and fold function of the legs.

But, they are badly threaded and you wouldn't use them anyway, right?

Adapters for other stand poles

K&M makes nice poles that are favorites of road techs.

Shown at right is a K&M

199 pole fitted with our adapter "slug" that coverts it to standard 7/8-27

thread so that it can be used with Surefoot. Great pole, with half the footprint.

The weight of the combination goes from 3.3 lbs. to 8.5 lbs, resulting in

significantly better stability.

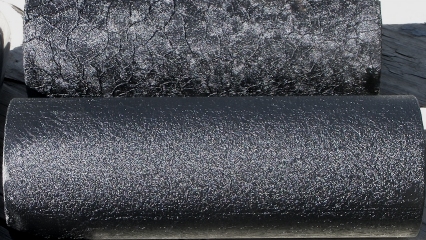

We have put much effort into developing strong castings, correcting stress

points by forming reinforcing ribs in the castings themselves, and shot-peening

the finished castings.

We work with a custom foundry to insure consistent iron formulations across multiple runs.

Tired of tip-toeing around on a riser to

keep from bending or breaking lightweight tripods? You can step on these

without fear of breaking or bending.

Surefoot

Longfoot

Surefoot and K&M 199 Pole with adapter

See special applications

"I'm SICK of badly threaded and machined stands."

All

holes for stand pole threading are machined, not drilled; using CNC

machinery and very tight tolerances so that the fine thread pitches involved

are cut to the correct depth with precision taps.

Our threads are so sharp that you can

actually use one of our bases to chase the threads on a stand pole.

"How big are they and what do they weigh?"

Surefoot and Longfoot footprints compared to a quality legacy round base, and an imported lightweight tubular base.

The Surefoot weight is a little less than a quality round base, and the Longfoot is a little more.

These bases are ideal for drum mics and straight stand or boom stand vocals

that do not move about. The stability is superior to round bases, and the

footprint is much smaller than lightweight folding stands.

You can't have stability without either a

big footprint or a weighted base. On a densely populated drum riser, we

maintain that the small footprint of a weighted base is better.

"How stable

is stable?"

In this picture, a Longfoot base with an Atlas MS20 stand pole and a

modified AKG

211 boom are suspending a gallon of water ( 8 pounds or 3.6kg ) beyond the

base radius.

The base can actually support that weight farther out, but it will bend the

boom.

This 211 Boom is modified with a lever lock

and locking clutches to take and hold the weight.

Why A Gallon of Water?

The heaviest microphone out

there is generally considered to be the legendary RCA Model 44 Ribbon Mic at

a little over 8 pounds, followed closely by the AEA 44 Reproduction at 7.9

pounds, so that is our reference.

You're not likely to run into them on the road, but for weight, they are the

big dogs.

Anything else is a piece of cake.

"How far into that kick drum do you need to go?"

This is

almost too much to ask even of a quality boom like this

modified K&M

21140, (note the bow in the boom tube) but even the smaller footprint Surefoot is capable of supporting an RE20 at this reach.

You probably would not want to use this combination at this reach, and this

is at the upper right corner of the stability envelope for the base, but it is

THAT stable.